As the time has improvised, a drastic transformation has left with a greater impact on the converters. If you are comfortable with the technical ideas, you may not need to know what the converters do because you already know that. However, we consider that most of the readers do not have a clear idea about the interior setup of the machines and therefore, they need to learn a bit about it.

Modern machines run on the electrical powers and the converters are the crucial ones that deal with the power conversion processes inside the machines. How do they do that? Consider that the main electrical circuit is bringing the AC current or alternating current. When that current will flow through a machine, the converter, especially an AC DC power converter will transform it into DC current and help the electrical flow run the machine. That is how the AC DC power converters work.

Are you surprised to find the name of the AC to DC power converters so early? This is what we are going to talk about now. Basically, the AC to DC power converters is used in the heavy industries and other sectors because due to the oscillatory motion of the AC power, the dissipation rate gets relatively lower. Therefore, there are lesser chances that the power will be converted into the heat energy. Actually, when the power is converted into the heat, it can be considered as a waste – which you can observe for the DC power systems.

This is the reason why, at the time of transferring the power, companies prefer AC power rather than the DC power. As an example, when you turn on a common electric-bulb, after a certain period, the electric bulb gets heated up and you cannot touch it with your naked hand. The DC power works directly and in order to run the machines uninterruptedly, DC power is considered as the best choice.

Then, why do you need to make custom made AC DC converters? This is so because, not all appliances can run on DC current, especially where transferring a large voltage of electrical power is required. At those points, AC current transferring system helps to transfer the power properly. It means, if somewhere it is required to transfer 24000V power, AC current is used because it can travel long distances due to it's to and fro motion and does not dissipate. However, the machines need the continuous flow of current, which the DC current can provide. The customised AC to DC converter can perfectly convert the AC current to the DC current so that the machines can continue with their flawless actions.

Are you keen to know where these custom made AC DC converters used? Look around yourself and you will find several types of machinery, which are using the custom made AC DC converters. The computers you use at your home or office have these sorts of converters, that can perfectly handle the power transfer and help the machines run properly.

It is better to mention that most of the machines run with the DC DC converters. These kinds of converters help machines run flawlessly or without any trouble. However, wherever a huge voltage is required to transfer to another medium, it is required to transfer it in the formation of AC current. After the transfer, the AC DC power converters convert the power into DC from AC.

Modifications of the modern times have vividly helped the industrial progress. As time passed by, the industrial and many other related sectors have embraced the revolutionary machines as well as various mechanical parts. The AC to DC power converters is the most upgraded and effective electronic machinery used in various sectors. Accepting the vast modification has actually benefitted the companies as well as various other sectors. The idea of modifications has not changed and in the upcoming times, it will be more effective for the internal and external activities of the companies and vehicles.

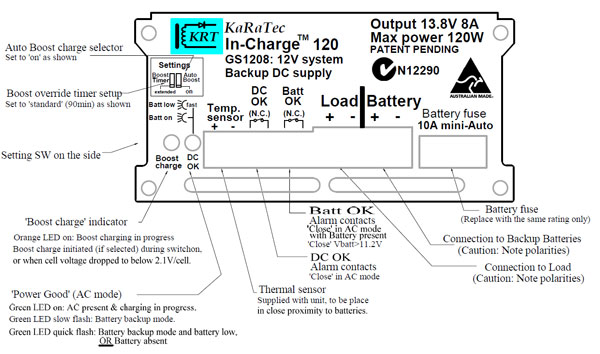

In this regard, Karatec can provide the best help to the clients. This company is a leading converter manufacturing company in Australia, which has changed the idea of technical evolution in the modern market.

Comments

Post a Comment